Outdoor industrial and logistics areas

Related Products

Discover other top-quality products from our range that are customised to meet your needs and exceed expectations. Explore now!

FAQs

Our street light poles are manufactured using high-quality steel, specifically grades such as ASTM A36, ASTM A572, and ASTM A595. These grades offer excellent strength, durability, and corrosion resistance, ensuring the poles can withstand various environmental conditions and provide long-lasting performance.

Our street light poles can accommodate a wide variety of lighting fixtures, including LED lights, high-pressure sodium lamps, and induction lights. We offer customizable mounting options to ensure compatibility with different fixture types, enhancing flexibility and functionality for various applications.

Utkarsh India street light poles enhance safety by providing adequate illumination for roads, walkways, parking lots, and other outdoor areas. Improved visibility helps prevent accidents, reduces crime rates, and promotes a sense of security for pedestrians and motorists alike.

We offer extensive customisation options for street light poles, including different heights, designs, finishes, and mounting configurations. Customers can choose from various pole styles, colors, and decorative features to match the aesthetic and functional requirements of their specific project.

Utkarsh India has an annual production capacity of 250,000 steel tubular poles.

Maintenance for street light poles is minimal but includes regular inspections to check for any structural damage or corrosion, cleaning to remove dirt and debris, and occasional repainting or refinishing to maintain aesthetic appeal and protect against weathering.

Utkarsh India offers a variety of design options for street light poles to suit different aesthetic and functional requirements. Customers can choose from a range of pole styles, including decorative designs, tapered or straight poles, and various heights.

We ensure the quality and durability of our street light poles through rigorous quality control measures, including material selection, fabrication processes, and finishing treatments. Our poles are made from high-grade steel and are tested for structural integrity, corrosion resistance, and overall performance to withstand various environmental conditions.

Utkarsh Steel Tubular Poles adhere to IS 2713 standards, incorporating the latest amendments, and feature hot-dip galvanizing coating thickness compliant with BS EN ISO: 1461 (BS 729)/ IS: 4759 specifications.

Yes, our street light poles can be integrated with renewable energy solutions, such as solar panels and wind turbines, to create energy-efficient lighting systems. This integration helps reduce energy consumption and supports sustainable development initiatives.

Why Choose Utkarsh India

-

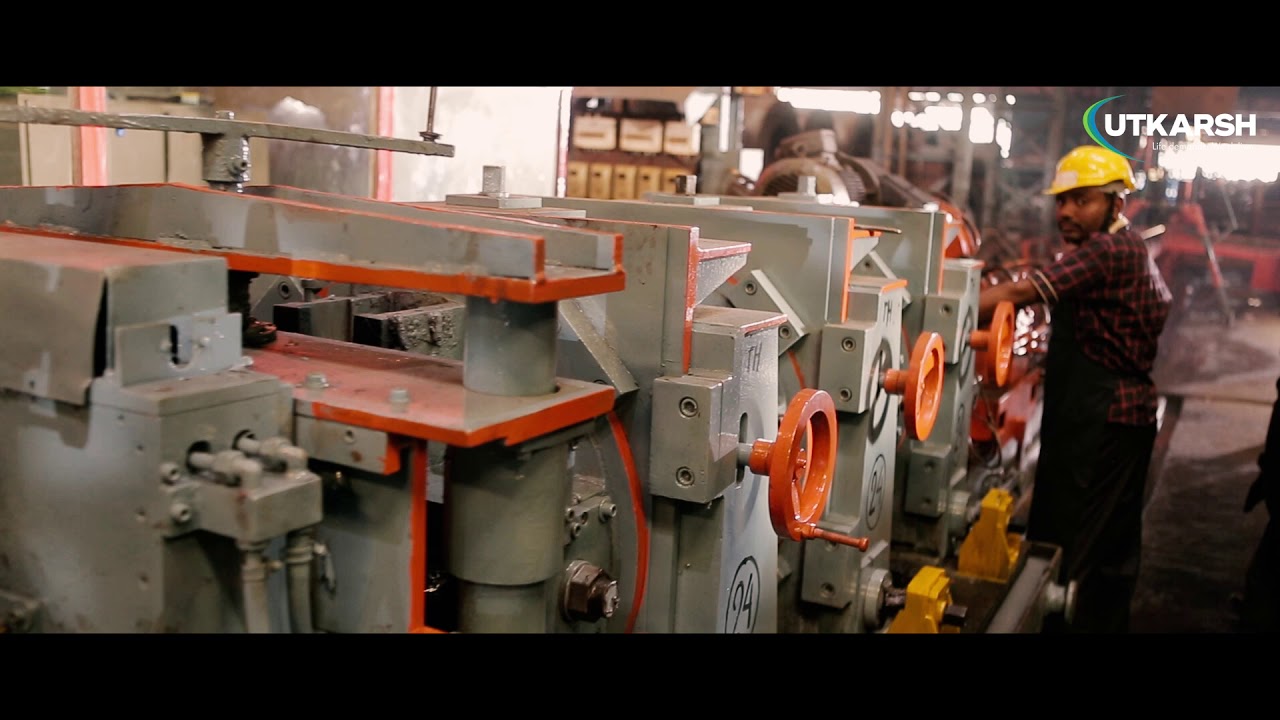

in steel fabrication, galvanisation, plastic extrusion and moulding, providing all infrastructural & manufacturing requirements under one roof.

-

along with cutting-edge testing facilities and R&D labs, and proven capability to accomplish manufacturing target deadlines.

-

for finished products and raw material storage, ensuring prompt availability and efficient supply chain management, with close connectivity via seaports, national highways and railways.

-

through raw material procurement from leading national and international manufacturers, ensuring responsible sourcing and superior traceability

-

with committed after sales support and assistance, ensuring seamless service and customer satisfaction at every step.

-

With forty years of experience in steel fabrication, galvanisation, plastic extrusion, and moulding, Utkarsh India is a leader in infrastructural manufacturing.

-

Our polygonal poles have undergone rigorous testing, including wind tunnel tests at IIT Kanpur and structural stability assessments from CSIR, Chennai, ensuring suitability for wind speeds up to 250 km/hr.

-

We produce 1000 lighting masts and 25,000 polygonal poles per month, leveraging well-trained manpower and advanced machinery. Our methodical process ensures timely delivery with minimal reworks and flawless finishes.

-

We have strategic procurement ties with SAIL and HZL for HR Coil and Zinc, and with various reputable companies for accessories. Our ready stock of materials ensures prompt production and delivery.

-

We utilise electroplated rope drums to combat corrosion and extend equipment life. All hardware is either made from stainless steel or hot-dip galvanised for enhanced durability.

-

Our five galvanising units employ a 7-tank process, using modern technology and supervised by qualified technicians, ensuring superior quality and longevity of the galvanised products.

-

Our in-house PU painting facility applies a protective and aesthetic coating over galvanised surfaces, enhancing product appearance and providing additional corrosion protection.

-

A dedicated logistics team oversees efficient transportation, with factories strategically located near NHAI, ports, and airports for seamless delivery.

-

Experienced service engineers provide comprehensive after-sales support, offering troubleshooting and technical assistance to ensure client satisfaction.

Related Videos

Explore more with our related videos, showcasing our products, manufacturing processes, solutions and more.