Transmission Lines

Related Products

Discover other top-quality products from our range that are customised to meet your needs and exceed expectations. Explore now!

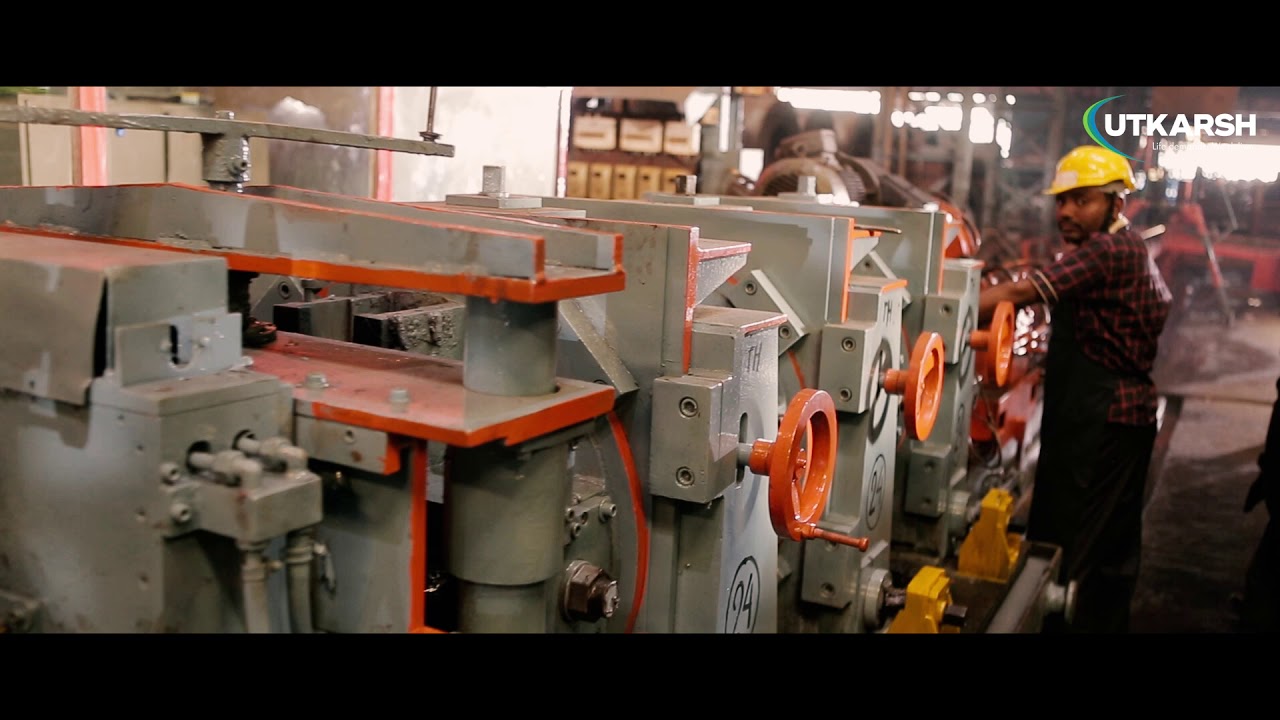

Manufacturing Process

Our meticulous and research-backed manufacturing process ensures durability, precision, and quality in every steel tubular pole we produce.

-

Receipt of Purchase Order

The manufacturing process begins with the receipt and thorough review of the purchase order (P.O.) to ensure all specifications and requirements are understood and planned for.

-

Receipt / Review of P.O.

We carefully review the purchase order, technical parameters (T.P.), and drawings to confirm all details and standards are met before proceeding.

-

Raw Material Indent

An indent is raised for procuring the necessary raw materials, ensuring we have all components needed for production.

-

Raw Material Received

Once the raw materials arrive, they are logged and prepared for inspection to maintain traceability and quality control.

-

Raw Material Inspection

Our quality control team conducts a rigorous inspection of the raw materials to verify they meet our high standards and specifications.

-

Production Planning

Detailed production planning is undertaken to streamline the manufacturing process, allocate resources efficiently, and meet delivery timelines.

-

Cutting/Swaging/Bending

The raw materials are cut, swaged, and bent into the required shapes and sizes, following the specific design and technical requirements.

-

Welding, Straightening & Other Accessories Fittings

Next, the components are welded, straightened, and fitted with necessary accessories to form the complete steel tubular poles, ensuring structural integrity and precision.

-

Floor Inspection

A comprehensive floor inspection is performed during and after the assembly process to identify and rectify any deviations from quality standards.

-

Surface Protection

The final step involves applying surface protection to the steel tubular poles, safeguarding them against corrosion and environmental damage, and ensuring a long-lasting finish.

Each stage of our manufacturing process is designed to uphold the highest standards of quality and reliability, ensuring our steel tubular poles are built to last and perform in any environment.

Quality Policies

Discover our cutting-edge infrastructure and commitment to unparalleled quality standards.

-

Advanced Galvanizing Facilities

With 5 in-house 12.5m long Hot Dip Galvanizing facilities, we use Special High Grade Zinc (99.995% purity) from Hindustan Zinc Limited to ensure standard coating and the best finish.

-

Stringent Quality Monitoring

Our QA/QC team ensures thorough quality checks at every production stage, from raw material procurement to dispatch, maintaining high standards for our solar panel poles.

-

Robust Production Capacity

As a leading steel tubular pole manufacturer, we produce over 2000 MT monthly and maintain a stock of 1000 MT, ensuring timely delivery of solar poles across India.

FAQs

Steel Tubular Poles (STP) are engineered to provide exceptional strength and stability, making them an ideal choice for various applications. Designed to withstand torsional stress, these poles offer minimum wind resistance and possess perfect elasticity to handle shocks, cyclones, thrust line breakages, and other external forces.

Steel tubular poles offer several advantages over other materials, including durability, strength, corrosion resistance, and low maintenance requirements. Unlike wood, steel poles do not rot or decay, and they can withstand harsh weather conditions and environmental factors. Additionally, steel poles are lighter in weight compared to concrete, making them easier to transport and install.

Utkarsh India offers a wide range of customizable steel tubular poles including street lighting poles, decorative lighting poles, solar poles, steel distribution & transmission poles, smart poles, steel tubular swaged poles, cantilever poles and traffic signal poles.

Our steel tubular poles are manufactured using high-quality steel sourced from reputable suppliers. We utilise various grades of steel, including ASTM A500, ASTM A572, and ASTM A595, depending on the specific requirements of the application. Each grade of steel is carefully selected to ensure optimal strength, durability, and corrosion resistance, meeting industry standards and specifications. Our poles undergo rigorous quality control measures to ensure their reliability and performance in diverse environments.

Yes, steel tubular poles are highly customisable and can be tailored to meet specific project requirements in terms of height, diameter, design, and finish. They can be fabricated with various accessories, such as brackets, arms, and luminaires, to accommodate different applications, such as lighting, signage, and surveillance.

Yes, steel tubular poles can be customised with various mounting options, including brackets, arms, and attachments, to accommodate specific requirements for mounting lighting fixtures, traffic signals, surveillance cameras, signage, and other equipment. Our experienced engineering team works closely with clients to design and fabricate poles that meet their unique project needs, ensuring optimal functionality and compatibility with the desired equipment.

Steel tubular poles are environmentally friendly and sustainable because they are made from recyclable materials and have a long service life. Additionally, their durability and low maintenance requirements reduce the need for frequent replacements, minimising waste generation and resource consumption over time.

Utkarsh India has the ability to produce 2,50,000 steel tubular poles per year.

Utkarsh India maintains stringent quality assurance measures throughout the manufacturing process of steel tubular poles to ensure that they meet industry standards and specifications. Our poles undergo rigorous testing for strength, durability, and corrosion resistance to ensure their reliability and performance in various applications.

Utkarsh India’s steel tubular poles conform to IS 2713 with the latest amendments & hot dip galvanising coating thickness as per BS EN ISO: 1461(BS 729)/ IS: 4759.

Utkarsh India provides comprehensive after-sales support for steel tubular poles, including technical assistance, maintenance services, and warranty coverage. Our dedicated customer support team is available to address any questions or concerns that may arise during the installation or operation of the poles, ensuring customer satisfaction and long-term reliability.

Why Choose Utkarsh India

-

in steel fabrication, galvanisation, plastic extrusion and moulding, providing all infrastructural & manufacturing requirements under one roof.

-

along with cutting-edge testing facilities and R&D labs, and proven capability to accomplish manufacturing target deadlines.

-

for finished products and raw material storage, ensuring prompt availability and efficient supply chain management, with close connectivity via seaports, national highways and railways.

-

through raw material procurement from leading national and international manufacturers, ensuring responsible sourcing and superior traceability

-

with committed after sales support and assistance, ensuring seamless service and customer satisfaction at every step.

-

With forty years of experience in steel fabrication, galvanisation, plastic extrusion, and moulding, Utkarsh India is a leader in infrastructural manufacturing.

-

Our polygonal poles have undergone rigorous testing, including wind tunnel tests at IIT Kanpur and structural stability assessments from CSIR, Chennai, ensuring suitability for wind speeds up to 250 km/hr.

-

We produce 1000 lighting masts and 25,000 polygonal poles per month, leveraging well-trained manpower and advanced machinery. Our methodical process ensures timely delivery with minimal reworks and flawless finishes.

-

We have strategic procurement ties with SAIL and HZL for HR Coil and Zinc, and with various reputable companies for accessories. Our ready stock of materials ensures prompt production and delivery.

-

We utilise electroplated rope drums to combat corrosion and extend equipment life. All hardware is either made from stainless steel or hot-dip galvanised for enhanced durability.

-

Our five galvanising units employ a 7-tank process, using modern technology and supervised by qualified technicians, ensuring superior quality and longevity of the galvanised products.

-

Our in-house PU painting facility applies a protective and aesthetic coating over galvanised surfaces, enhancing product appearance and providing additional corrosion protection.

-

A dedicated logistics team oversees efficient transportation, with factories strategically located near NHAI, ports, and airports for seamless delivery.

-

Experienced service engineers provide comprehensive after-sales support, offering troubleshooting and technical assistance to ensure client satisfaction.

Related Videos

Explore more with our related videos, showcasing our products, manufacturing processes, solutions and more.