Transmission & Distribution Poles

Transmission & Distribution Poles

As the top manufacturers and suppliers of steel tubular poles in India and abroad, Utkarsh India specialises in producing efficient solutions for power transmission and distribution. At our worldclass ERW plants, we integrate cutting-edge technology with Quality Assurance system to offer top-grade transmission and distribution poles to our customers that effectively meet their expectations and specifications. Based on central and state DISCOMS requirements in floated tender, we take pride in accomplishing the supply of lakhs of poles in varying lengths and weights. Manufactured in both painted and galvanised forms, each of our products in this category conforms to IS:2713 standard.

Recognised for exceptional strength and stability, our transmission and distribution poles are extremely capable of withstanding harsh weather conditions and torsional stress, making it highly reliable for installing at remote locations. These poles are also highly elastic to endure several challenges like cyclones, shocks and thrust line breakages, making them efficient to meet a wide range of requirements.

Manufactured with premium quality raw materials acquired from industry players like SAIL and TATA Steel, we have the capability to manufacture 2,50,000 poles every year that offer high durability and longevity. Known for our commitment to timely delivery, excellent logistics management and after sales service, we take pride in supplying our poles to multiple turnkey projects across the country.

-

250000

ANNUAL PRODUCTION CAPACITY

-

5

HOT DIP GALVANISING FACILITIES

-

1000

READY STOCK OF POLES

Single Side Single Barrier, Single Side Double Barrier, Double Side Single Barrier, Double Side Double Barrier

- Indian Design Crash Tested Under EN 1317-2 at Natrax (2 Mtr Centre to Centre)

- International Design Licensed under EN 1317-2 (2.0 & 2.66 Mtr Centre to Centre)

- Safety Standards On-ground safety barrier, conforming to Class H2W3, H2W4, H2W5 Certified in accordance with European Standard EN 1317: Part 2 Adherent to IRC 119 – 2015, SP 73:2007, SP 73:2015, SP 84:2014, SP 87:2019 recommendations

- Materials 3.0mm/5.0mm thick HR Coil Fe360, Fe410, and Fe510 raw material grades Raw materials conform to IS 5986/2062/10748 or equivalent standards

- Dimensions 3.0*4318mm (underneath width) Beam dimensions 150755mm (underneath width) Post and Spacer dimensions 502mm width for optimal coverage and protection

- Crash Testing Crash tested for: Bus of 13000 kgs and Car of 900 kgs

- Precision crafted for maximum effectiveness Thrie beam crash barriers are engineered with precision to ensure optimal performance during high-impact collisions, providing reliable protection and reducing the risk of severe accidents.

- Top-notch durability and structural integrity These highway crash barriers are designed to withstand extreme conditions, maintaining their structural integrity even under the harshest environmental and mechanical stresses, ensuring long-term safety.

- Made with meticulously selected materials Each metal beam crash barrier is constructed using high-quality, corrosion-resistant materials, such as galvanised steel, ensuring longevity and consistent performance across diverse climates and terrains.

- Specially designed for enhanced road safety and reliability The unique triple-wave design of thrie beam barriers offers superior impact absorption, effectively controlling vehicle deflection and preventing road departure, thus enhancing overall road safety.

- Competitive Thrie metal beam crash barrier price Despite their advanced features and superior construction, these barriers are competitively priced, offering excellent value for money in road safety investments.

- Efficiently absorbs and redirects collision energy Thrie metal beam crash barriers are designed to absorb and redistribute the force of impact during collisions, significantly reducing the risk of severe vehicle damage and occupant injury.

- Higher containment levels for improved protection These highway crash barriers provide enhanced containment levels, offering superior protection by preventing vehicles from breaching the barrier, especially in high-impact scenarios.

- Conforms to prevalent international standards Thrie beam crash barriers are manufactured in compliance with global road safety standards, ensuring they meet the rigorous requirements for performance and safety in various countries.

- Prompt PAN India delivery We offer swift and reliable delivery across India, ensuring that your project timelines are met without any delays.

- Made with high-quality, carefully-sourced raw materials Our barriers are crafted using top-grade raw materials sourced from trusted suppliers, guaranteeing durability and resilience under harsh environmental conditions.

- Robust construction ensures long-lasting performance The sturdy construction of these barriers ensures they withstand continuous exposure to the elements and provide long-term protection on highways and bridges.

Product Application

Product Application

Here’s a roundup of the versatile usage of our steel tubular poles across various projects for power transmission and distribution.

Market Growth

Market Growth

The steel tubular poles market is witnessing significant growth, driven by increasing demand for durable and cost-effective lighting solutions in urban and rural infrastructure projects. India is projected to produce about 300 million tons of pipes and tubes by the end of FY 2030–31, with advancements in materials and manufacturing technologies enhancing product longevity and reliability.

Related Products

Related Products

Discover other top-quality products from our range that are customised to meet your needs and exceed expectations. Explore now!

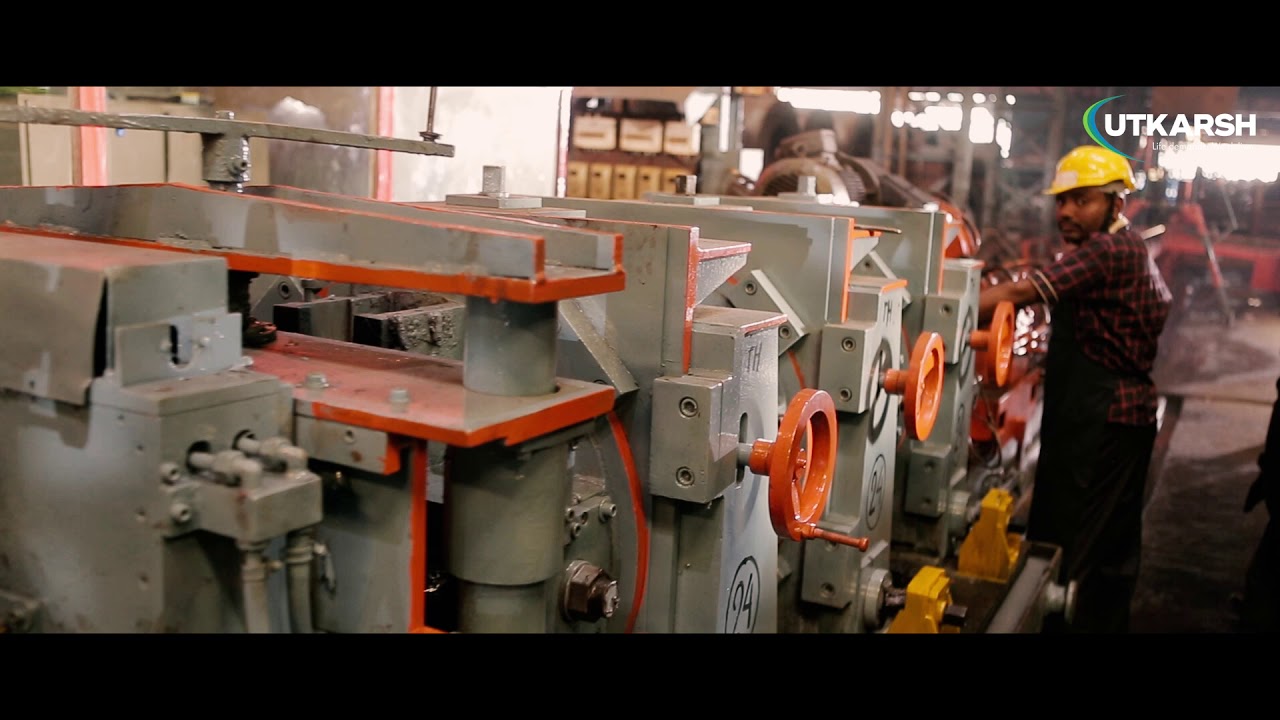

Manufacturing Process

Manufacturing Process

Our meticulous and research-backed manufacturing process ensures durability, precision, and quality in every steel tubular pole we produce.

-

Receipt of Purchase Order

The manufacturing process begins with the receipt and thorough review of the purchase order (P.O.) to ensure all specifications and requirements are understood and planned for.

-

Receipt / Review of P.O.

We carefully review the purchase order, technical parameters (T.P.), and drawings to confirm all details and standards are met before proceeding.

-

Raw Material Indent

An indent is raised for procuring the necessary raw materials, ensuring we have all components needed for production.

-

Raw Material Received

Once the raw materials arrive, they are logged and prepared for inspection to maintain traceability and quality control.

-

Raw Material Inspection

Our quality control team conducts a rigorous inspection of the raw materials to verify they meet our high standards and specifications.

-

Production Planning

Detailed production planning is undertaken to streamline the manufacturing process, allocate resources efficiently, and meet delivery timelines.

-

Cutting/Swaging/Bending

The raw materials are cut, swaged, and bent into the required shapes and sizes, following the specific design and technical requirements.

-

Welding, Straightening & Other Accessories Fittings

Next, the components are welded, straightened, and fitted with necessary accessories to form the complete steel tubular poles, ensuring structural integrity and precision.

-

Floor Inspection

A comprehensive floor inspection is performed during and after the assembly process to identify and rectify any deviations from quality standards.

-

Surface Protection

The final step involves applying surface protection to the steel tubular poles, safeguarding them against corrosion and environmental damage, and ensuring a long-lasting finish.

Each stage of our manufacturing process is designed to uphold the highest standards of quality and reliability, ensuring our steel tubular poles are built to last and perform in any environment.

Quality Policies

Quality Policies

Discover our cutting-edge infrastructure and commitment to unparalleled quality standards.

-

Advanced Galvanizing Facilities

With 5 in-house 12.5m long Hot Dip Galvanizing facilities, we use Special High Grade Zinc (99.995% purity) from Hindustan Zinc Limited to ensure standard coating and the best finish.

-

Stringent Quality Monitoring

Our QA/QC team ensures thorough quality checks at every production stage, from raw material procurement to dispatch, maintaining high standards for our solar panel poles.

-

Robust Production Capacity

As a leading steel tubular pole manufacturer, we produce over 2000 MT monthly and maintain a stock of 1000 MT, ensuring timely delivery of solar poles across India.

FAQs

FAQs

Steel Tubular Poles (STP) are engineered to provide exceptional strength and stability, making them an ideal choice for various applications. Designed to withstand torsional stress, these poles offer minimum wind resistance and possess perfect elasticity to handle shocks, cyclones, thrust line breakages, and other external forces.

Steel tubular poles offer several advantages over other materials, including durability, strength, corrosion resistance, and low maintenance requirements. Unlike wood, steel poles do not rot or decay, and they can withstand harsh weather conditions and environmental factors. Additionally, steel poles are lighter in weight compared to concrete, making them easier to transport and install.

Utkarsh India offers a wide range of customizable steel tubular poles including street lighting poles, decorative lighting poles, solar poles, steel distribution & transmission poles, smart poles, steel tubular swaged poles, cantilever poles and traffic signal poles.

Our steel tubular poles are manufactured using high-quality steel sourced from reputable suppliers. We utilise various grades of steel, including ASTM A500, ASTM A572, and ASTM A595, depending on the specific requirements of the application. Each grade of steel is carefully selected to ensure optimal strength, durability, and corrosion resistance, meeting industry standards and specifications. Our poles undergo rigorous quality control measures to ensure their reliability and performance in diverse environments.

Yes, steel tubular poles are highly customisable and can be tailored to meet specific project requirements in terms of height, diameter, design, and finish. They can be fabricated with various accessories, such as brackets, arms, and luminaires, to accommodate different applications, such as lighting, signage, and surveillance.

Yes, steel tubular poles can be customised with various mounting options, including brackets, arms, and attachments, to accommodate specific requirements for mounting lighting fixtures, traffic signals, surveillance cameras, signage, and other equipment. Our experienced engineering team works closely with clients to design and fabricate poles that meet their unique project needs, ensuring optimal functionality and compatibility with the desired equipment.

Steel tubular poles are environmentally friendly and sustainable because they are made from recyclable materials and have a long service life. Additionally, their durability and low maintenance requirements reduce the need for frequent replacements, minimising waste generation and resource consumption over time.

Utkarsh India has the ability to produce 2,50,000 steel tubular poles per year.

Utkarsh India maintains stringent quality assurance measures throughout the manufacturing process of steel tubular poles to ensure that they meet industry standards and specifications. Our poles undergo rigorous testing for strength, durability, and corrosion resistance to ensure their reliability and performance in various applications.

Utkarsh India’s steel tubular poles conform to IS 2713 with the latest amendments & hot dip galvanising coating thickness as per BS EN ISO: 1461(BS 729)/ IS: 4759.

Utkarsh India provides comprehensive after-sales support for steel tubular poles, including technical assistance, maintenance services, and warranty coverage. Our dedicated customer support team is available to address any questions or concerns that may arise during the installation or operation of the poles, ensuring customer satisfaction and long-term reliability.

Why Choose Utkarsh India

Why Choose Utkarsh India

-

in steel fabrication, galvanisation, plastic extrusion and moulding, providing all infrastructural & manufacturing requirements under one roof.

-

along with cutting-edge testing facilities and R&D labs, and proven capability to accomplish manufacturing target deadlines.

-

for finished products and raw material storage, ensuring prompt availability and efficient supply chain management, with close connectivity via seaports, national highways and railways.

-

through raw material procurement from leading national and international manufacturers, ensuring responsible sourcing and superior traceability

-

with committed after sales support and assistance, ensuring seamless service and customer satisfaction at every step.

-

With forty years of experience in steel fabrication, galvanisation, plastic extrusion, and moulding, Utkarsh India is a leader in infrastructural manufacturing.

-

Our polygonal poles have undergone rigorous testing, including wind tunnel tests at IIT Kanpur and structural stability assessments from CSIR, Chennai, ensuring suitability for wind speeds up to 250 km/hr.

-

We produce 1000 lighting masts and 25,000 polygonal poles per month, leveraging well-trained manpower and advanced machinery. Our methodical process ensures timely delivery with minimal reworks and flawless finishes.

-

We have strategic procurement ties with SAIL and HZL for HR Coil and Zinc, and with various reputable companies for accessories. Our ready stock of materials ensures prompt production and delivery.

-

We utilise electroplated rope drums to combat corrosion and extend equipment life. All hardware is either made from stainless steel or hot-dip galvanised for enhanced durability.

-

Our five galvanising units employ a 7-tank process, using modern technology and supervised by qualified technicians, ensuring superior quality and longevity of the galvanised products.

-

Our in-house PU painting facility applies a protective and aesthetic coating over galvanised surfaces, enhancing product appearance and providing additional corrosion protection.

-

A dedicated logistics team oversees efficient transportation, with factories strategically located near NHAI, ports, and airports for seamless delivery.

-

Experienced service engineers provide comprehensive after-sales support, offering troubleshooting and technical assistance to ensure client satisfaction.

Related Videos

Related Videos

Explore more with our related videos, showcasing our products, manufacturing processes, solutions and more.